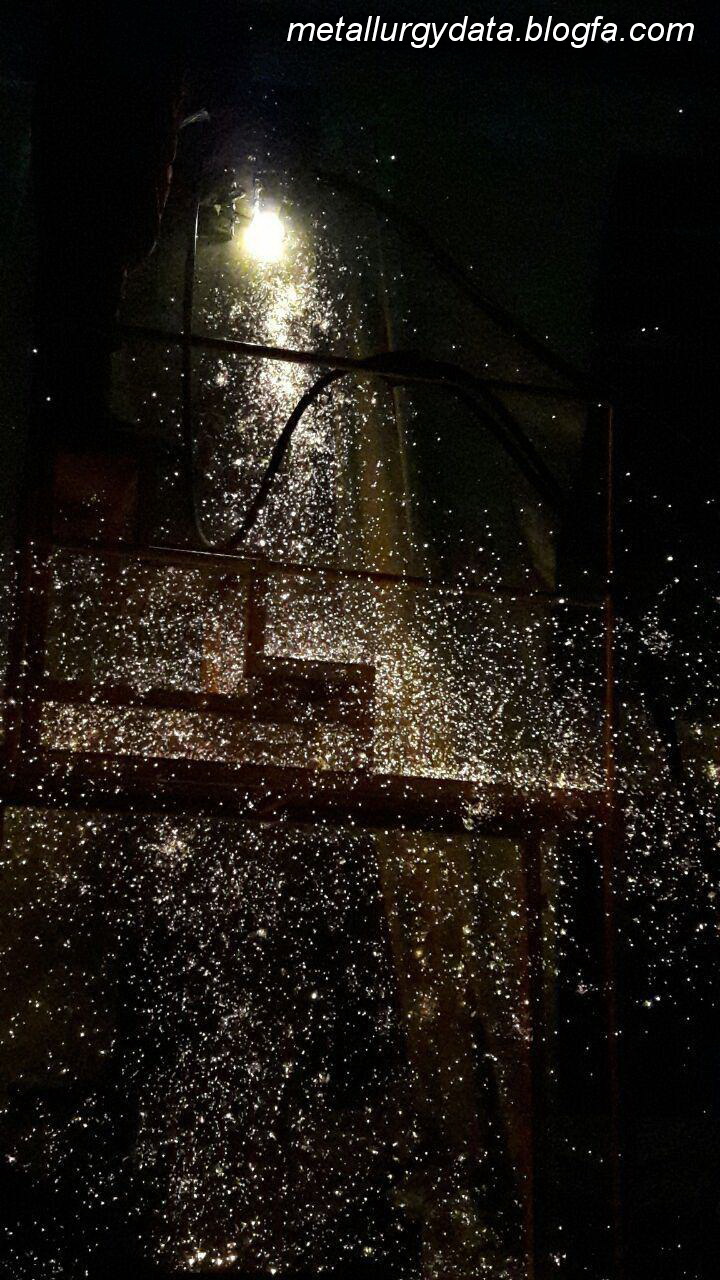

عملیات گوجینگ،Arc Gouging،برشکاری با الکترود گرافیت

Air carbon arc cutting

Air

carbon arc cutting previously known as air arc cutting,is an arc

cutting process where metal is cut and melted by the heat of a carbon

arc. Molten metal is then removed by a blast of air. It employs a

consumable carbon or graphite electrode to melt the material, which is

then blown away by an air jet.

This

process is useful for cutting a variety of materials, but it is most

often used for cutting, and #gouging aluminum, copper, iron, magnesium,

and carbon and stainless steels. Because the metal is blown away by the

air jet, it does not need to be oxidized. This process differs from

plasma cutting operations because in air carbon cutting, an open, or

un-constricted, arc is used, and the arc operates separately from the

air jet.

Air

pressures for the jet usually vary from 60 to 100 psig. The carbon

electrode can be worn away by oxidation from heat buildup. This can be

reduced by coating the carbon electrodes with copper.

The

sharpened carbon electrode is drawn along the metal, an arc forms and

melts the metal. The air jet is then used to blow away molten material.

This can be dangerous as the molten material can be blown substantial

distances. The process is also very noisy.